———

Scope of application:

life water tank: 40-160m3

fire water tank:80-300m3 Power: 550W/750W/1100W Disinfection method: external ozone disinfection

→产品详情

Component: control box (ozone generator, controller, circulating water pump, jet device, etc.) and inlet & outlet pipe connections.

Scope of application: secondary water supply high-level water tank, reservoir, clean water pond of waterworks, disinfection of water reuse, pool water treatment system, landscape water disinfection, beverage & food industries, sterilization & algae killing of fire water tank and small self-contained water source disinfection etc.

Working principle: ozone is a strong oxidizer whose oxygen atoms oxidize the cell walls of bacteria until puncture and kill them by the unsaturated bonds. Ozone has good decolorizing, oxidation and deodorizing functions, and no secondary residue or pollution occurs during the transformation to oxygen.

External Water Tank Self-cleaning Sterilizer Parameter

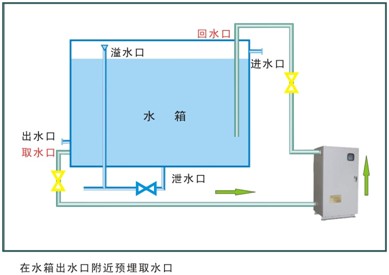

Installation diagram

Installation instructions :

1.Pool water is pumped by a built-in circulating pump in sterilizer, then disinfected by the pressure of the circulating pump and released to the inlet of the tank.

2.The shell has five layers of corrosion protection and thermal insulation, it can be installed outdoors and rain - proof & anti - freezing.

3.The installation should be as close as possible to the water tank and minimize water intake pipe and return pipe, but the water intake and water return inlet of the tank should be as far away as possible to prevent short circuit during water treatment. The water intake is connected near the outlet pipe of water tank (pool).

4.After treatment by the sterilizer, the water is returned to the top of the water tank (pool) which near the inlet. A water outlet can be opened at the top of the tank (pool) , the water return pipe can be inserted into the depth of ≧2/3H below the water surface.

5.The distance from the sterilizer to the wall of water tank (pool) should be ≧0.6m, the operating and maintenance space should be more than 0.5m before and after the sterilizer. The inlet and outlet pipes and sewage pipes shall be connected with movable joints, for maintenance. Sewage outfall shall be equipped with the necessary sewage pipe to connect to the drain.

6.PVC or stainless steel can be used as the material of these pipes.

7.Y-strainer should be installed on the water intake pipe to protect the circulating water pump in the sterilizer.

8.Fully automatic operation of microcomputer and no need for personal care when working normally. It can automatically detect and shut off the power when there is no water to protect the water pump and electric machine.

留言板

山东良成环保科技股份有限公司

400-005-1005