———

Killing bacteria & legionella ﹡ Inhibiting algae growth ﹡ Preventing equipment pipeline corrosion ﹡Lowering turbidity ﹡ Reducing suspended matter, Fe & Mn content, yellow water and bad smell.

Scope of application:

life drinking water, secondary living pool, water tank sterilization, fire pool, etc.

Specification:

Input power:AC220/380V,50Hz Working pressure : ≤0.6 MPa

Applicable water temperature:0℃~50℃ Disinfection rate : >99.5%

Algae removal : >99.9% Killing legionella : international standards Electrical conductivity:> 40μs/cm

→产品详情

Component: box, circulating pump, microelectrolytic disinfection unit, intelligent control unit, suction and return water pipes, etc.

Working principle : the sterilizer is based on microelectrolysis, which causes the dissolved chlorine ions and water molecules in water by electrochemical reaction to produce the following oxidizing substances: hypochloric acid, chlorine dioxide, reactive oxygen, molecular chlorine, etc. All water and inner wall of water tank(pool) are treated by these oxidizing substances through diffusion and circulation, which can destroy bacteria and algae microbes to achieve the effect of disinfection andalgae removal.

Installation instructions :

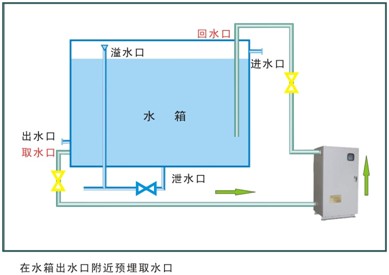

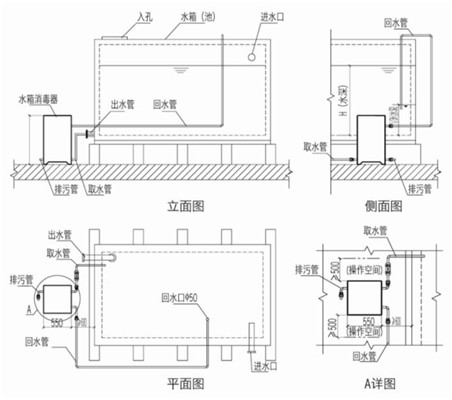

1.Pool water is pumped by a built-in circulating pump in sterilizer, then disinfected by the pressure of the circulating pump and released to the inlet of the tank.

2.The shell has five layers of corrosion protection and thermal insulation, it can be installed outdoors and rain - proof & anti - freezing.

3.The installation should be as close as possible to the water tank and minimize water intake pipe and return pipe, but the water intake and water return inlet of the tank should be as far away as possible to prevent short circuit during water treatment. The water intake is connected near the outlet pipe of water tank (pool).

4.After treatment by the sterilizer, the water is returned to the top of the water tank (pool) which near the inlet. A water outlet can be opened at the top of the tank (pool) , the water return pipe can be inserted into the depth of ≧2/3H below the water surface.

5.The distance from the sterilizer to the wall of water tank (pool) should be ≧0.6m, the operating and maintenance space should be more than 0.5m before and after the sterilizer. The inlet and outlet pipes and sewage pipes shall be connected with movable joints, for maintenance. Sewage outfall shall be equipped with the necessary sewage pipe to connect to the drain.

6.PVC or stainless steel can be used as the material of these pipes.

7.Y-strainer should be installed on the water intake pipe to protect the circulating water pump in the sterilizer.

8.Fully automatic operation of microcomputer and no need for personal care when working normally. It can automatically detect and shut off the power when there is no water to protect the water pump and electric machine.

Installation diagram

留言板

山东良成环保科技股份有限公司

400-005-1005