【Product features】

1.Shell material: the reaction chamber is made of imported 304 stainless steel with thickened wall thickness and100% quality guarantee.

2.Processing technology: product is fully automatic welding, all saddle backs are smooth and no dead angle, the inner and outer polished high brightness cavity greatly enhances the radiation intensity of ultraviolet light. With thickened chamber design, its bearing pressure can reach 0.8Mpa. Strict air & water pressure tests can completely prevent water leakage.

3.Independently developed sanitary spiral cleaning ring: it can tightly wrap tube and clean thoroughly, pollution-free and suitable for the requirements of clean water quality.

4.Ultraviolet lamp: we use the high quality of low pressure high strength lamp in the world. Lamp is installed in quartz socket tube of reactor, paralleled to the warter flow direction. The effective working life of lamp is no less than 9000 hours. It produces 254 nm ultraviolet output and is equipped with high efficiency electronic ballast, the service life and using effect will be enhanced and the sterilization rate can be up to 99.99%.

5.Quartz socket tube: sterilizer use more than 90% high transmittance (UVT) quartz socket tube. It has two type: single-ended and double-ended openings. Good ultraviolet transmittance can ensure high-intensitive ultraviolet output.

6.Electronic ballast: as the core component of the whole system, we use electronic preheating/instant high voltage start type of ballast, its advantage is high stability and reliability.

7.Seal ring: we use food grade transparent silica gel which has trapezoid structure instead of O-ring. It can avoid water leakage caused by improper installation.

8.Ultraviolet radiation intensity sensor and monitor: sensor can monitor the output intensity of the ultraviolet disinfection system on-line in real time, and output 0-5v or 4-20mA mixed signal, which will be provided to monitor. When receiving signals from sensor, monitor can set the alarm value of the radiation intensity and the service life of lamp tube according to requirement. Real-time monitoring of the system can ensure the normal operation of sterilizer.

9.Quartz socket tube cleaning system: there are two kinds of cleaning systems manual and full-automatic, each of them can achieve on-line cleaning without stopping. The quartz socket tube will scale after long-term contact with water, so it must be cleaned effectively. Our cleaning ring’s structure is simple and not easy ageing. The flexible cleaning parts of cleaning ring can actively adapt to the quartz socket tube. Even if there is deviation in the installation, the cleaning effect can be guaranteed and without wearing the tube.

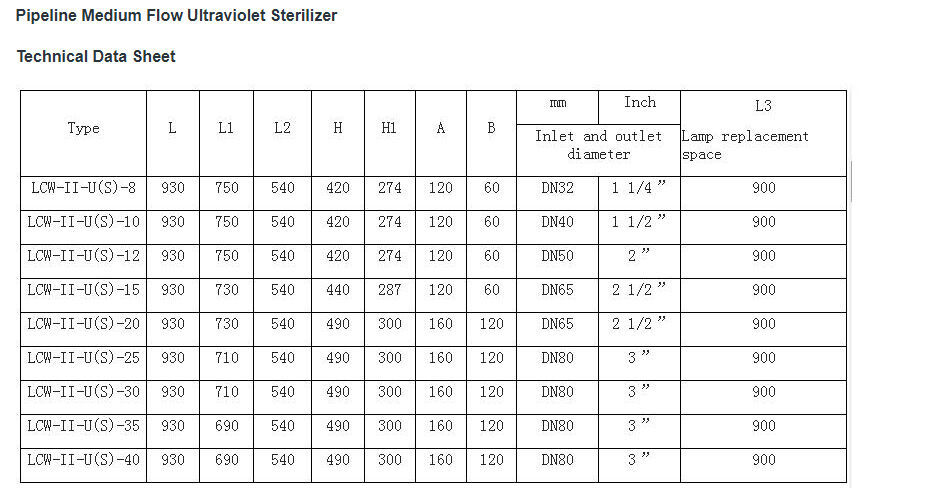

Remark : 1.Power requirment: AC220V/50Hz; 2. Lamp service life: no less than 10,000 hours; 3. Reactor is made of SUS304 or SUS316 stainless steel; 4.The shell is mechanically polished; 5.Bearing pressure: 0.6Mpa; 6.Optional: a.sample connection, b.ultraviolet intensity detector, c. manual/automatic cleaning function, d.alarm indication; 7.Power line: line length 2.4m, three-pole aviation plug; 8. If the treated water amount is more than 150m³/h, it can be customized according to user requirements; 9. Inlet and outlet directions can be customized according to user requirements.

Control box :

The box is equipped with microprocessor which has I/O interface and distribution system that provides power to the ultraviolet sterilizer, sensor & automatic cleaning system. Ultraviolet intensity, operating time and state of the lamp can be continuously monitored online and the results are output to the operation interface of control panel.

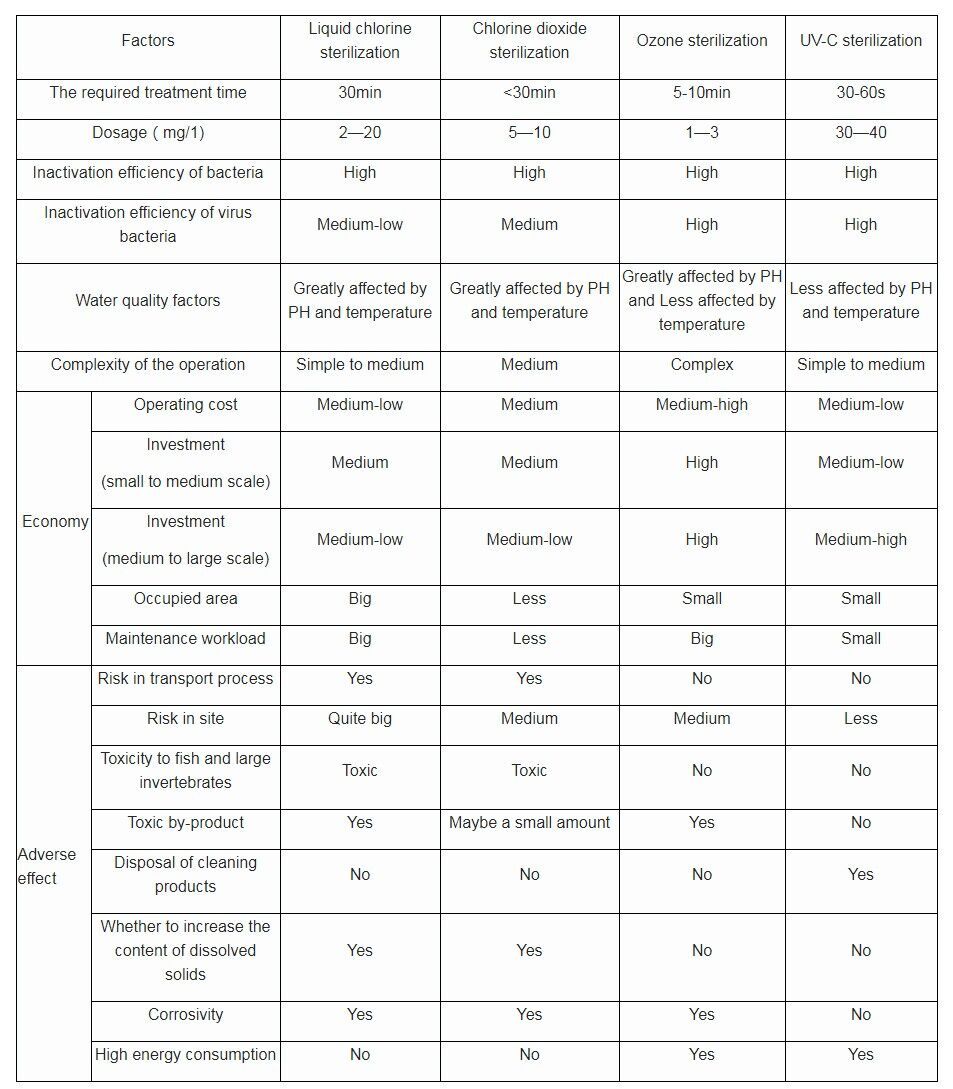

Comparison of sterilization methods

Factors affecting ultraviolet performance and efficiency :

• Water temperature

• Water velocity

• Ultraviolet transmittance

• Content of suspended matter in water

• Particle size distribution in water

• Hydrodynamic design of sterilizer

• Lamp performance

• Lamp arrangement

• Quartz socket tube scale coefficient

• Ballast performance and lamp matching

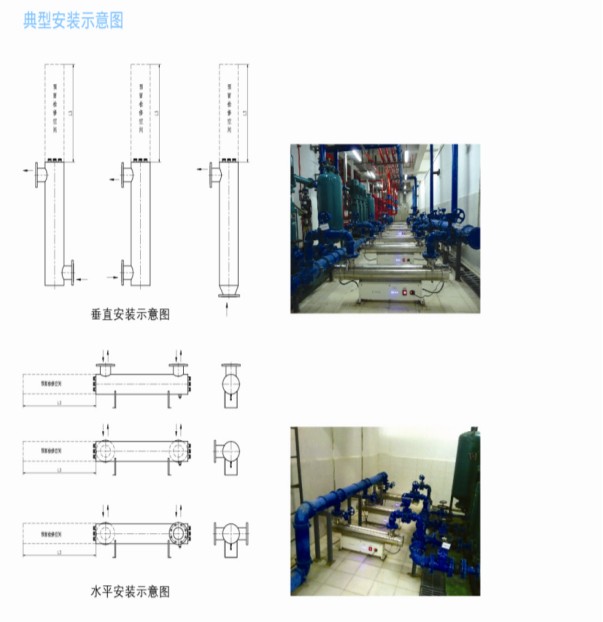

Installation instructions :

• Quartz socket tube and ultraviolet lamp are valuable and fragile, they should be prevented from collision during transportation, installation and use.

• Ultraviolet light can cause serious damage to the eyes and skin, it is strictly prohibited to use the naked eye to look at exposed ultraviolet light, anti-uv glasses are necessary when checking.

• Unplug the power plug first before opening the shell to repair ultraviolet sterilizer.

• For the first time to use, it needs to operate with water for 5-8 minutes, so as to remove air and impurities in the tube and make the ultraviolet lamp reach the normal working state.Water cannot be used as a test sample or drunk directly during this period.

• When the quality of raw water is lower than the national drinking water standard, such as chroma is higher than 15 degree, turbidity is higher than 5 degree, iron content is higher than 0.3 mg/L, other methods should be used to reach the purification standards before the treatment by the ultraviolet sterilizer.

• When the total quantity of bacteria exceeds 3000 /ml and the number of Coliform groups exceeds 800 /L, multiple ultraviolet sterilizers should be used in series or water volume should be reduced as appropriate to achieve purification standards.

• When installing ultraviolet sterilizer, by-pass pipeline and stop valve should be added to facilitate equipment maintenance and repair.

• The pipeline distance between reactor and the user's water intake point is minimized to avoid secondary pollution caused by the back-end pipe network.

• Lamp cannot be energized without water.

• It is strictly prohibited to switch the lamp frequently to avoid affecting the service life of lamp.

• When the water flow is greater than the maximum flow, more than two sterilizers can be installed in parallel on the pipe line.

• It is strictly prohibited to exceed the rated working pressure during use, and the equipment components should be prevented from being impacted by violent water flow.

• After the reactor of the ultraviolet sterilizer is fully filled with water, the valve is opened completely to avoid water hammer.